|

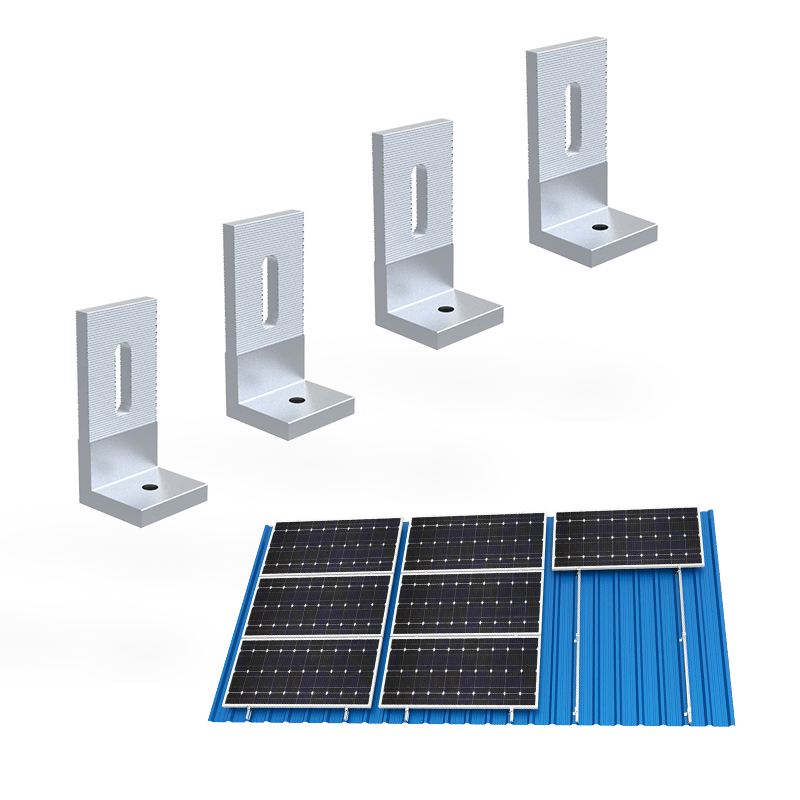

Installation Site:

|

Roof mount

|

|

Tilt Angle:

|

0-45 deg

|

|

Max wind speed load:

|

60m/s

|

|

Snow Load :

|

1.4kn/m^2

|

|

L feet Height:

|

80mm, 84mm, 125mm, 160mm

|

Various L feet heights to meet the heat dissipation needs of solar panels

(1) Waterproof performance

Most photovoltaic bracket systems adopt a waterproof design, including rubber gaskets or special sealants to ensure that there is no risk of leakage after installation.

(2) Easy installation

The bracket design is modular, which can be assembled quickly and reduce construction time.

Lightweight materials such as aluminum alloy and stainless steel are easy to carry and install.

(3) Sturdy and durable

Using high-quality materials (such as 6005-T5 aluminum alloy, stainless steel 304/410, etc.), it has excellent corrosion resistance.

The bracket structure is precisely designed to withstand severe weather such as strong winds and heavy snow.

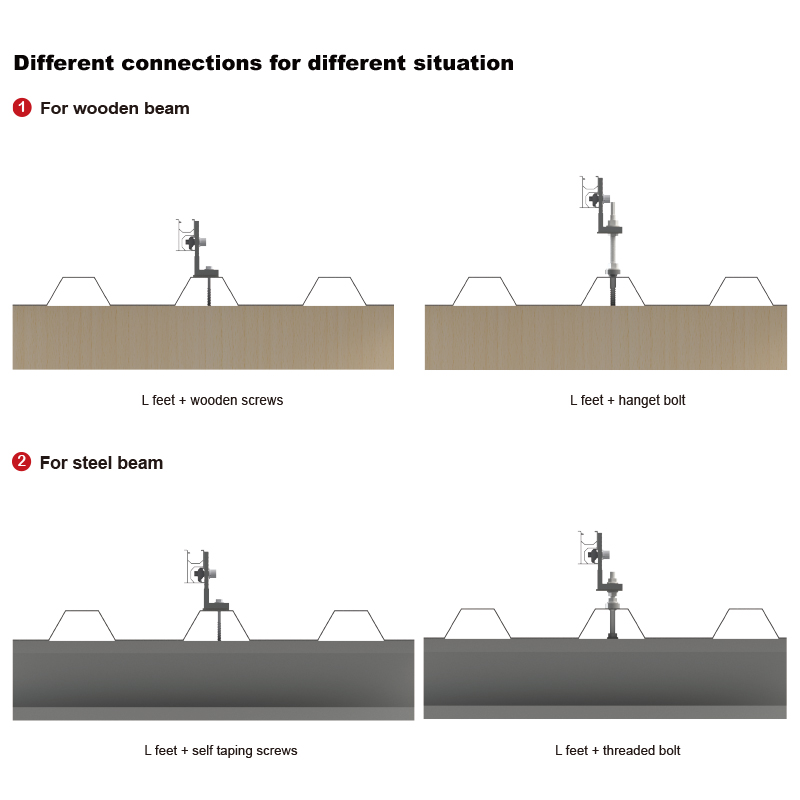

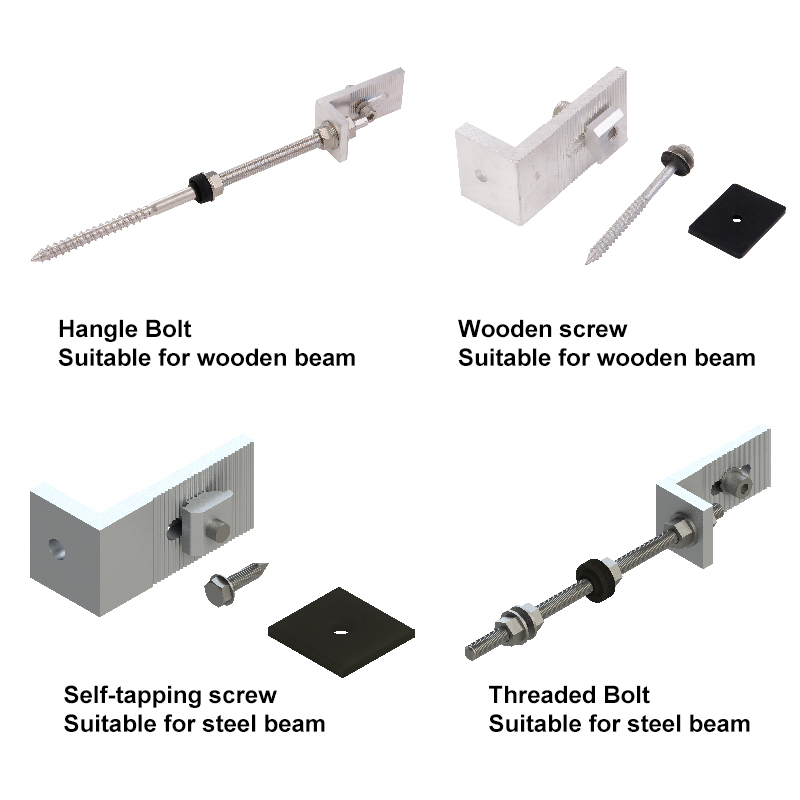

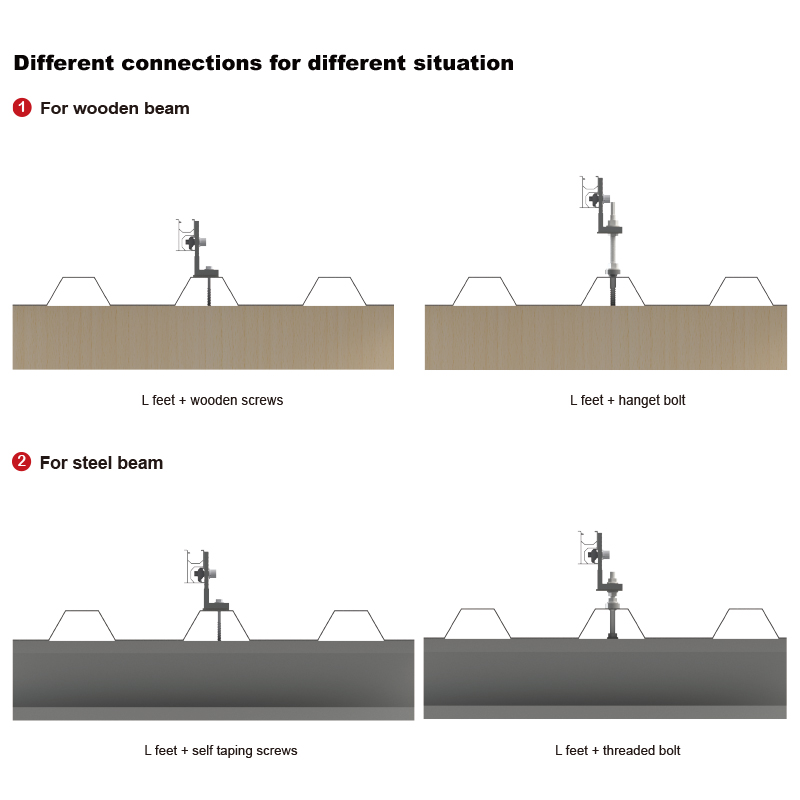

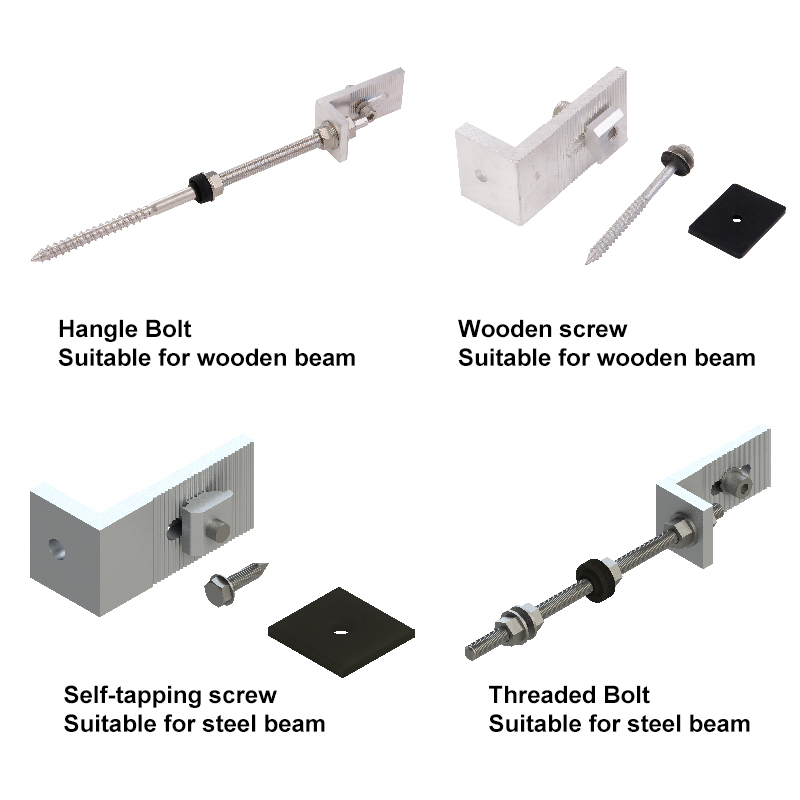

(4) Strong adaptability

The bracket can be customized according to different roof types and is compatible with various corrugated, trapezoidal and standing seam metal roofs.

It is compatible with different brands and types of photovoltaic modules.

(5) Cost saving

The bracket system is reasonably designed and the material usage is optimized, which is more economical than other complex systems.

Applicable scenarios

Industrial plant roofs: Large iron roofs are suitable for installing centralized photovoltaic systems.

Commercial buildings: Provide green energy for commercial places.

Rural houses: Small photovoltaic systems meet household electricity needs.

Precautions

1. Waterproof treatment

When drilling holes for installation, ensure that each hole is sealed with a gasket or sealant to prevent rainwater leakage.

Check the sealing part regularly to prevent aging or loosening.

2. Roof load-bearing capacity

Before installing the photovoltaic system, it is necessary to confirm the load-bearing capacity of the iron roof to ensure safety.

3. Windproof design

In strong wind areas, it is necessary to select a bracket system with excellent wind resistance and fix it with reinforcements.

Q1: Are you a Factory?

A: Yes. We are a factory who is specialized in the producing the solar mounting kits in Xiamen, China. Our goods including solar mounting components, also the whole mounting system, including roof mounting, Ground Mounting, Carport, Solar Farm and also the OEM service.

Q2: How can we guarantee quality?

A: Always a pre-production sample before mass production;

Spot check will be done for each procedure during our goods preparing. And before shipment, all will be check again.

Third Party Inspection is accepted.

Q3: Can I get sample before we place the order ?

A: Yes. Samples can be avaible anytime if you need.

Q4: How can I get a quotation?

A: 1. If for the regular components, just show us the item No. and quantity, we will quote you immediately.

2. If for the OEM componnets, show us the technical drawing or the sample, we will show you our drawing and then quote you after got your confirmation to the drawing.

3. If for the whole mounting solution, to make sure can provide the most appropriate quotation, some more information about the project will be needed:

1) Solar panel qty. and dimension (LxWxT) of the panel

2) Panel/ structure tilt angles

3) Max wind load and snow load

4) Panel layout plan or the roof/ground size (Lx W)

5) Others it may need according to different solution

English

English français

français Deutsch

Deutsch русский

русский español

español português

português Nederlands

Nederlands العربية

العربية 日本語

日本語 한국의

한국의

IPv6 network supported

IPv6 network supported online service

online service